3-Way Directional Valve

(To be removed) Three-port two-position directional control valve

The Hydraulics (Isothermal) library will be removed in a future release. Use the Isothermal Liquid library instead. (since R2020a)

For more information on updating your models, see Upgrading Hydraulic Models to Use Isothermal Liquid Blocks.

Libraries:

Simscape /

Fluids /

Hydraulics (Isothermal) /

Valves /

Directional Valves

Description

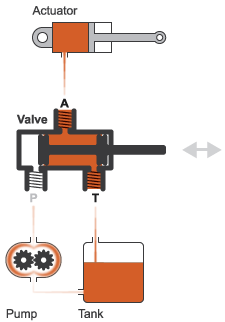

The 3-Way Directional Valve block represents a directional control valve with three ports and two positions, or flow paths. The ports connect to what in a typical model are a hydraulic pump (port P), a storage tank (port T), and a single-acting actuator (port A). Fluid can flow from the pump to the actuator via path P-A and from the actuator to the tank via path A-T.

Typical Valve Setup

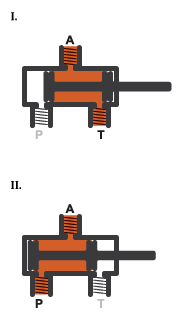

In the default configuration, one valve position corresponds to the A-T flow path maximally open and the P-A flow path maximally closed (position I in the figure). The second valve position corresponds to the P-A flow path maximally open and the A-T flow path maximally closed (position II in the figure). A translating spool serves as the valve control member and determines the position that the valve is in—I, II, or in between.

Valve Positions

Physical signal port S controls the spool displacement. In the default configuration, a zero displacement corresponds to a fully closed valve between positions I and II. A negative displacement shifts the spool toward valve position I. A positive displacement signal shifts the spool toward valve position II. The spool displacement acts indirectly by setting the spool position relative to each flow path—a length known here as the orifice opening. The orifice opening in turn determines the opening area of the respective flow path.

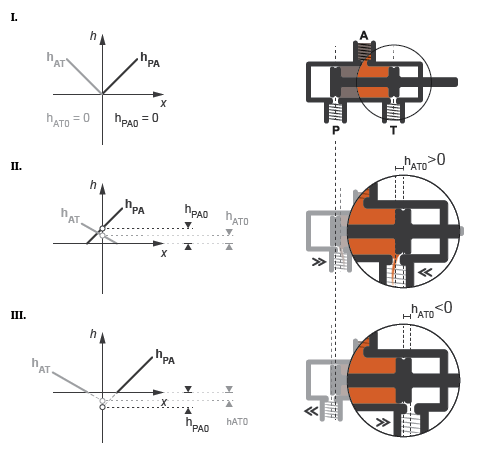

Orifice Openings and Offsets

The orifice opening of a flow path depends partly on its opening offset—the orifice opening of a flow path at zero spool displacement. The block models only the dynamic effects of the opening offsets. An offset can be due to a change in distance between ports or spool lands—the thick disks built into the spool to obstruct flow. It can also be due to a change in the thicknesses of the spool lands. The orifice openings are computed separately for each flow path in terms of the respective opening offset:

where:

hPA and hAT are the orifice openings of the P-A and A-T flow paths. The orifice openings are computed during simulation.

hPA0 and hAT0 are the opening offsets of the P-A and A-T flow paths. The opening offsets are specified in the Valve opening offsets tab.

x is the spool displacement relative to what in the zero-offset case is a fully closed valve. The spool displacement is specified through physical signal port S.

The figure shows the effects of the opening offsets on the orifice openings. Plot I corresponds to the default configuration with both opening offsets equal to zero. Plot II corresponds to a valve with both opening offsets greater than zero and plot III to a valve with both opening offsets smaller than zero. These cases are similar in behavior to zero-lapped (I), underlapped (II) and overlapped (III) valves. The valve schematics to the right show what the offsets might look like for the A-T flow path.

Zero (I), Positive (II), and Negative (III) Opening Offsets

An underlapped valve is always partially open and allows some flow at all spool displacements. An overlapped valve is fully closed over an extended range of spool displacements and requires longer spool travel to open. The table summarizes the opening offsets for zero-lapped, underlapped, and overlapped valves. Other configurations are possible—e.g., with one opening offset positive and the other negative.

| Valve Lapping | Opening Offsets |

|---|---|

| Zero-lapped (default) | Both zero |

| Underlapped | Both positive |

| Overlapped | Both negative |

Opening Area Parameterizations

The Model parameterization setting determines the

calculations used for the opening areas of the flow paths—or, in the

Pressure-flow characteristic case, the volumetric

flow rates. The calculations are based on orifice parameters or tabulated data sets

specified in the Model Parameterization tab. The block uses the

same data for both flow paths if the Area characteristics

parameter in the Basic Parameters tab is set to

Identical for all flow paths and different data

otherwise. Model parameterizations that you can select include:

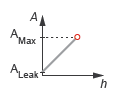

Maximum area and opening— Specify the maximum opening area and the corresponding orifice opening. The opening area is a linear function of the orifice opening,where A is the opening area and h the orifice opening of a given flow path. The subscript

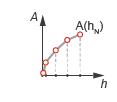

Maxrefers to a fully open orifice and the subscriptLeakto a fully closed orifice—one with internal leakage flow area only. The figure shows a plot of the linear function A(h).

Area vs. opening table— Specify the opening area at discrete orifice openings as a 1-D lookup table. The opening area is computed for a given orifice opening by interpolation or extrapolation of the tabulated data. The figure shows a conceptual plot of the tabulated function A(h).

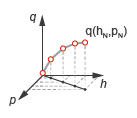

Pressure-flow characteristic— Specify the volumetric flow rate at discrete orifice openings and pressure differentials as a 2-D lookup table. The opening area is computed for a given orifice opening and pressure differential by interpolation or extrapolation of the tabulated data. The figure shows a conceptual plot of the tabulated function q(h, p).

Volumetric flow rates are computed analytically in the Maximum

area and opening and Area vs. opening

table parameterizations. The calculations are based on

additional block parameters such as the flow discharge coefficient and account

for the effects of flow regime—laminar or turbulent. Regime transition

occurs at the specified critical laminar flow ratio or critical Reynolds number.

The Maximum area and opening and Area

vs. opening table parameterizations also account for a small

leakage area associated with the valve spool-to-bore clearance. The leakage area

ensures that portions of the hydraulic network never become isolated when a flow

path is closed. Isolated, or “hanging”, network portions affect

computational efficiency and can cause simulation to fail.

The effects of flow regime and internal leakage are assumed to be reflected in

the tabulated flow rate data specified directly in the

Pressure-flow characteristic

parameterization.

Structural Component Diagram

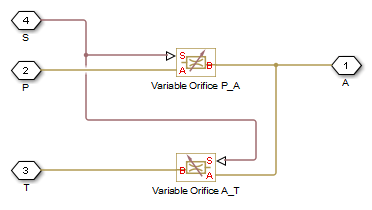

The block is a composite component with two Variable Orifice blocks driven by a

single physical signal. Block Variable Orifice P_A represents the

P-A flow path. Block Variable orifice

A_T represents the A-T flow path. The physical

signal is specified through Connection Port block S.

The Orifice orientation block parameters are set so that a

positive signal acts to open Variable Orifice P_A while closing

Variable Orifice A_T. A negative signal has the

opposite effect, acting to open Variable Orifice A_T while

closing Variable Orifice P_A.

Valve Structural Diagram

Assumptions

Fluid inertia is ignored.

Spool loading due to inertial, spring, and other forces is ignored.

All valve orifices are assumed identical in size unless otherwise specified.